Cartridge Loaders:

History of the Pneumatic Cartridge Loaders

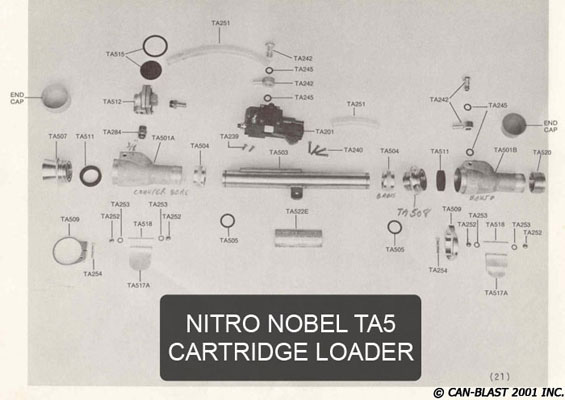

The standard TA5 series pneumatic cartridge loader was produced by Nitro Nobel. This loader had a nickel plated brass alloy cartridge chamber and chamber flaps that were made of a bronze alloy. This series of loader was only capable of loading 25mm (1") diameter cartridges.

The cartridge loader was often referred to as the "Swedish Air Loader" over in European countries.

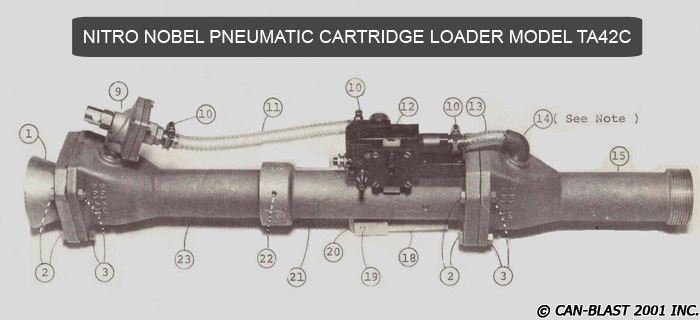

Two modified version of the TA5 series loaders were produced with Stainless steel cartridge chamber and aluminum flaps. The TA32 and TA42 models had an enlarged cartridge chamber and longer chamber flaps, so that 1-1/4" cartridges could be used.

Also the new design allowed the sections of the castings to be bolted together versus having sections thread together as in the TA5 model.

Can-Blast Inc. started over 30 years ago and began to modify the Nitro Nobel loaders to suit the Canadian mining market. The modified loaders had an additional 'L' added to the model number to indicate they had received these modifications. Ex. TA42L

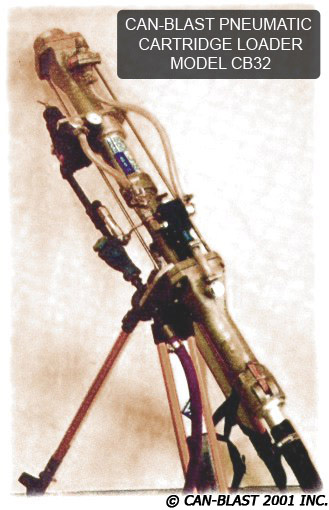

In 1993 Can-Blast eventually started to fabricate and assemble loaders in Canada. These models were models were named CB32 and CB42.

At this time an number of improvements were implemented to the loader body castings, the red air block was redesigned and the air system was modified to improve operation.

The Canadian made castings were thicker at the bolting flange then the TA series. The addition of tie rods through the castings provided a ruggedness to the loader and solved the problem of the castings coming loose in the field.

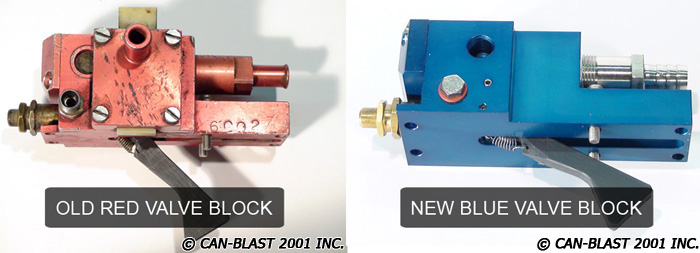

The re-design of the air valve block increased performance and reduced oiling maintenance from every second shift to once every 100 hours, the nylon slide on/off valve was replaced with an external ball valve, mating components made of aluminum where switched to steel to prevent thread stripping, the air valve block color was changed from red to blue to distinguish new models from the old.

Can-Blast offered replacement parts and some modifications for the older red valve air blocks. Some of today's production replacement parts continue to fit these valves.

A "Y" strainer and pilot pressure filter were added to the air supply line to offer additional protection. The Air Pressure Regulator used on the early production loader was the same as the units used on the TA5 series. These where retained to the mounting bracket by four bolts. This regulator model was discontinued by the manufacturer, and the replacement unit was retained by a large plastic nut.

To reduce stress to the piping system and components an additional support bracket was added.

In 2001 the whole air system on the loaders was upgraded from 3/8" piping and components to 1/2". This has improved the performance of the CB42 due to the larger volume in the cartridge chamber but increased speed is also seen on the CB32.

In 2002 several customers required the loader to cycle extremely fast so that two men can feed cartridges into the loader breach. Can-Blast releast a series of service notes explaining how to modify existing loader components and a series part upgrades that needed to be changed to acheive the high loader cycle speed.

After 2002 all pneumatic cartridge loaders that are manufactured have all of the upgrades applied to them. They are distigushed by having an "R" at the end of the model number. Ex. CB32R or CB42R